Aluminum Castings Company Fundamentals Explained

Table of ContentsAluminum Castings Company for BeginnersAn Unbiased View of Aluminum Castings CompanyAluminum Castings Company Can Be Fun For EveryoneThe 4-Minute Rule for Aluminum Castings CompanyThe 2-Minute Rule for Aluminum Castings CompanySome Known Factual Statements About Aluminum Castings Company About Aluminum Castings Company

Below are descriptions of two unique armed forces components. A fire reductions housing is made to snuff out fires in armored automobiles, ensuring that the lorry can withstand direct hits without endangering the security of its owners. A projectile nose item, which is installed at the idea of a projectile, must be specifically cast to sustain the G-forces produced throughout launch.Manufacturers are consistently seeking faster and more reliable manufacturing approaches. Light weight aluminum die spreading has actually shown to meet and go beyond these demands with its high-speed manufacturing capacities, outmatching various other alloys.

Aluminum spreading is an affordable selection due to its fast manufacturing and very little finishing requirements. The reduced material prices and reliable manufacturing processes cause financial savings that benefit both firms and customers. When subjected to air, light weight aluminum castings create an oxidized surface that enhances their long life and dependability. This natural oxidation procedure prolongs the lifespan of aluminum elements, using higher value to customers.

Aluminum Castings Company for Dummies

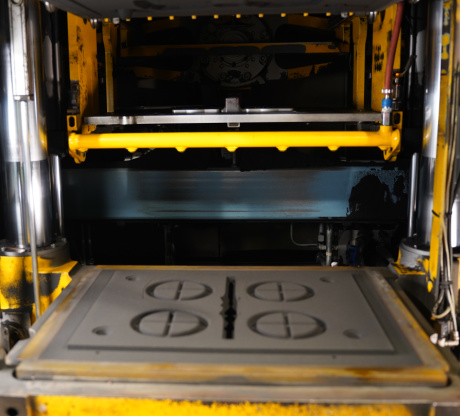

A favorable benefit of aluminum actors components is the layer of aluminum oxide that forms immediately after the component is removed from the mold and mildew. The light weight aluminum oxide layer offers a wall of protection versus rust and rust. A regular approach for casting light weight aluminum is to pour liquified aluminum right into a steel mold and mildew that has been accuracy machined to make sure that the cast item will certainly have an extremely smooth and refined surface area.

Our company believe nobody should opt for less than an area where difficult work and abilities are highly valued. At Wisconsin Light Weight Aluminum Foundry, we test our employees to exceed and beyond, and award them for it, too.

4 Simple Techniques For Aluminum Castings Company

The term "lost-wax spreading" can additionally refer to contemporary financial investment casting procedures. Financial investment casting has been utilized in numerous kinds for the last 5,000 years. In its earliest forms, beeswax was utilized to create patterns necessary for the casting process. Today, even more innovative waxes, refractory materials and specialist alloys are normally made use of for making patterns.

The surface quality with this will however be somewhat limited by the fidelity of the machine, yet instead of actors and function the Light weight aluminum to accomplish a much better surface area, why not sand/ complete the rapid prototype component? This might be made complex by your base product, yet this is quite typical.

Getting The Aluminum Castings Company To Work

If you want a mirrorlike surface, you'll need to polish it whatever you do - https://sandbox.zenodo.org/records/397992. Unless you have an excellent sand wheel, you're most likely going to get some tiny surface voids below and there which may be a problem if you actually need a mirror smooth finish. If this is a one off or brief run, investment spreading from an RP component is possibly mosting likely to be the most effective wager

However once more, you're mosting likely to intend to find a casting shop that has actually done this in the past. Stratasys (or whatever equipment you're making use of) can probably provide you some referrals. FDM surface top quality is pretty far from mirrorlike- you'll desire to smooth it out as much as possible prior to casting. It's a lot much easier to sand ABS than aluminum.

Unknown Facts About Aluminum Castings Company

Take an appearance over below Detailed, patient-specific structural version service from 3D Systems precision healthcare services They discuss Castform or thermojet Wax Patterns 3D Solution has the largest portfolio of 3D Printers. We provide 3D Printing options for manufacturing, prototyping, casting, dental and much more. If you're in the US you might wish to speak to these individuals: They are a model vendror based in Seattle and click here for more use a solution called Quickcast.

The Basic Principles Of Aluminum Castings Company

i have actually done some sand spreading of aluminum and it's most likely a great way to go, like everyone else has said, depending upon the time you're ready to take into the part after the spreading is full. you can, nevertheless use an RP component as a pattern for sand spreading Fantastic details! I may still contact Moeller - I want to eventually try a little run of vessels and the less work I need to to postcast, the better.

Once more, you're going to want to discover a spreading shop that has actually done this in the past. Stratasys (or whatever device you're utilizing) can probably give you some references. FDM surface area top quality is pretty much from mirrorlike- you'll want to smooth it out as a lot as feasible prior to casting. It's a great deal less complicated to sand ABS than aluminum.

Aluminum Castings Company Things To Know Before You Buy

Take a look over right here Comprehensive, patient-specific anatomic version service from 3D Equipments precision health care solutions They mention Castform or thermojet Wax Patterns 3D Systems has the largest portfolio of 3D Printers. We provide 3D Printing remedies for production, prototyping, spreading, oral and a lot more (Sand Foundry). If you remain in the United States you might intend to speak to these people: They are a prototype vendror based in Seattle and offer a service called Quickcast

I have actually never functioned with them nonetheless, yet listened to some terrifying things. This process is typically utilized for HIGH resistance components to be cast in Titanium for like airplane things.

i have actually done some sand spreading of light weight aluminum and it's possibly a great way to go, like everybody else has actually stated, depending upon the time you agree to take into the component after the spreading is total. you can, however make use of an RP component as a pattern for sand casting Great information! I may still get in touch with Moeller - I would love to inevitably try a little run of vessels and the less job I need to to postcast, the much better.